What are the main uses of plywood in load restraint?

- Plywood is often used when stacking pallets on top of one another which is called ‘interlayer packing’. It prevents the goods and pallets from rubbing against one another.

- Plywood is used to prevent any movement of the load, often in tandem with shoring bars which is a technique called ‘blocking’.

- Ply is often used when loading steel-based stillages onto a steel deck to increase friction.

- Plywood can be used behind a loading rack to spread the load and support product packaging.

What is blocking for load restraint and why do it?

- Blocking involves positioning stock against the headboard, tailboard, step deck, or using restrained plywood sheeting, empty pallets, shoring bars, airbags, etc., to reduce load shifting when a ‘Full Load’ is not attained.

- Blocking is used to prevent the pallet or load from moving sideways, forwards or rearwards within the trailer.

- When using containers, if every pallet/reel space is not used, blocking or timber chocks can be used to prevent movement and to ensure restraint for securing the load is available and used.

Blocking tips using plywood

- Ensure blocking material is capable of transportation forces. Pallets must have their main bearers blocking the packs (i.e. bearers vertical).

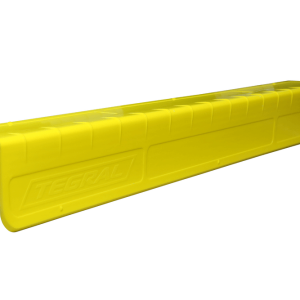

- A Shoring Bar is generally made from galvanised steel tube and used to secure blocking or loads inside Pantech and Van trailers.

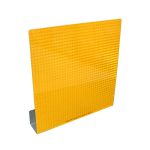

- Plywood sheets can be places vertically, horizontally or even diagonally for blocking, depending on the load and your company’s requirements. Make sure that all your load restraint is compliant and up to date with the latest load restraint guide.

Here are some different examples of blocking using plywood: