All team members need the right education and expertise to make sure that equipment is loaded and unloaded securely and safely. Being introduced to internal policies, procedures, and processes is part of this. Only those with the requisite training and expertise should load and unload machinery. If not managed appropriately, heavy loads can be dangerous.

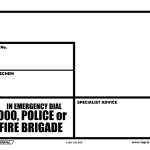

A detailed risk assessment that takes into account each phase of the work, including site risks and hazards, loading, transit, and unloading, should be conducted before loading and unloading equipment. This is especially important when dealing with a new product or area, as well as when unfavourable weather is present.

Each company, to the extent of its ability to affect and control the job, is jointly responsible under workplace health and safety legislation for the health and safety of people participating in the work. Together, they must guarantee that risks are reduced or if that is not practicable, eliminated.

Below are the loading and unloading procedures and requirements that must be considered by every transport company.

When loading/unloading with a mobile plant, consider the following traffic management measures:

- Exclusion zone and safety zone Specify a pedestrian exclusion zone around the truck.

- Specify a safety zone for the driver – eg at the front of the truck, in the amenities area, or the cabin, if it is safe to do so.

- Erect sturdy barriers, such as fences or gates, around the safety zone – or, if these are unavailable, use chains or tape.

- No one should enter the exclusion zone without the mobile plant operator’s approval. The mobile plant operator should not begin loading/unloading until everyone is clear of the exclusion zone.

- Maintaining an exclusion zone around the truck while loading/unloading will also eliminate the risk of anyone being hit by falling loads.

- Communication

- Use an effective communication system between the mobile plant operator and the driver – eg hand signals may be suitable in some workplaces, two-way radios in others.

- Use signs, lights, alarms, and the like to indicate loading/unloading is in progress.

- Mobile plant

- Ensure operators are appropriately licensed, where necessary, and trained to load safely following road safety legislation.

- Fit speed limiting devices, where appropriate.

- Fit reversing sensors, cameras, or audible warning devices.

- Ensure tyres, windscreens, mirrors, reversing sensors, and the like are well maintained.

- Ensure mobile plant is appropriate for the loads and workplace.

- Work environment

- Ensure adequate lighting.

- Provide a safe loading/unloading surface area.

- Personal protective equipment – eg high-visibility work gear.

It is also essential to put measures in place to ensure the truck cannot move during loading/unloading.

Consider using dock locks, air-brake isolation-interlock devices, barriers, or ‘stop’ signals. Also, prevent unauthorised access to ignition keys and cabin, and ensure systems are in place that alerts the driver when it is safe to leave.