Prior to applying lubrication, the device should be cleaned as instructed by the manufacturer (details are available in the manufacturer’s handbook seen below.

The following are suggestions for choosing lubricants:

- Silicon is recommended by the manufacturer as of the publishing date.

- Make use of lubrication that is suitable with rubber parts.

- It is advised that the application nozzle/straw that comes with the lubricant spray system be used to help with direction and penetration. It is advised to have a permanent nozzle/straw attachment.

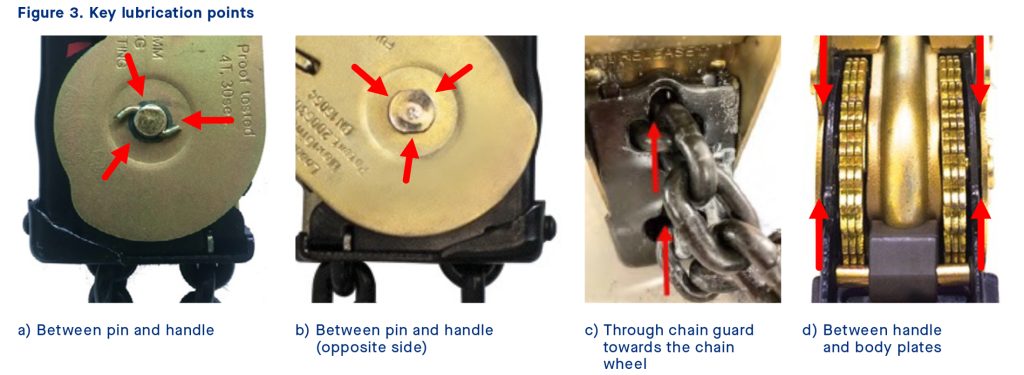

Among the lubrication points are:

- All interfaces and contact points that move in relation to one another.

- Some suggested lubricant application sites are shown in Figure 3. The user is free to apply to additional places not on this list.

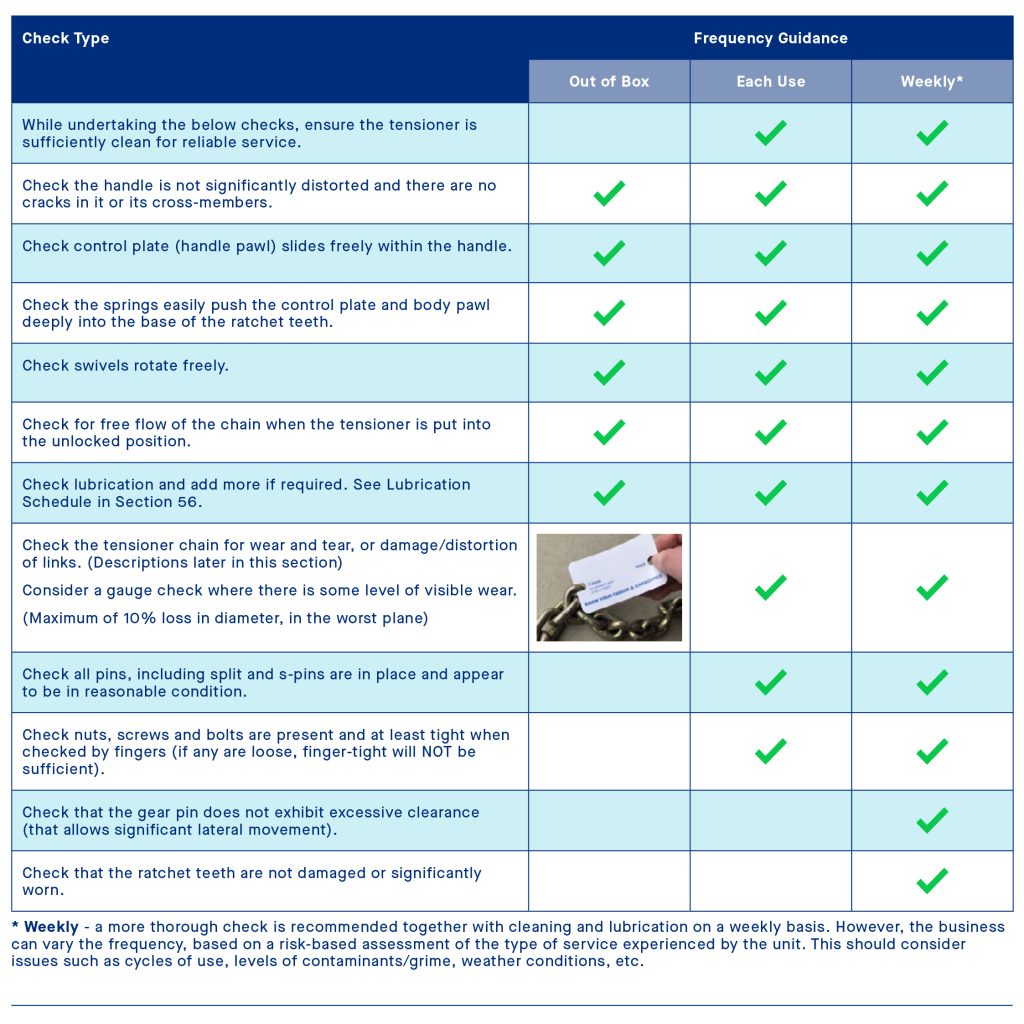

Checking Tensioner Parts and Performance

In-service inspections are those carried out by the driver, user, or other qualified persons who have received the necessary training.

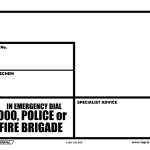

The following checks should be included. The table below includes important checks and maintenance activities that will help to control the hazards involved with tensioner usage.

The Maxibinder tensioners have spare parts available from Tegral Transport Equipment, therefore replacement of the parts is often undertaken considering the cost-benefit relationship. Any user or organisation should visit a skilled expert or the manufacturer if they believe additional substantial maintenance is required.