Efficient load restraint plays a critical role in the transportation industry, ensuring the safe and secure delivery of goods. Traditional methods of load securing often involve timber bearers which can be time-consuming and less effective. However, the BettaHaul Bearer System is transforming load restraint with its advanced rubber dunnage solution. In this blog, we will delve into the BettaHaul Bearer System, its advantages, and how it is revolutionizing dunnage in logistics.

The BettaHaul Bearer System:

www.tegral.com.au/bettahaul

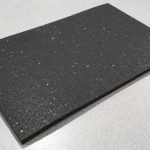

The BettaHaul Bearer System is a modular and customizable bearer solution designed to replace traditional timber bearers. It consists of rubber bearers of 2 different heights and clamping attachments that can be selected based on specific load requirements. The system’s key objective is to provide a secure and stable platform for long-span loads, ensuring maximum safety during transportation.

Advantages of the BettaHaul Bearer System:

a. Oil Resistant Rubber: Unlike timber, the rubber formulation used in the BettaHaul Bearer System does not absorb oil or water, maintaining a consistent coefficient of friction. This feature ensures stability and minimizes the rolling effect during transport, enhancing load safety.

b. High Coefficient of Friction: The BettaHaul Bearer System’s rubber design facilitates efficient load restraint by providing a high coefficient of friction. This reduces the need for excessive lashing and ensures a secure grip, minimizing load movement and potential damage.

c. Modular and Customizable: The system’s modular nature allows for easy customization based on specific load requirements. With different bearer heights and clamping attachments, transport providers can select the optimal configuration to suit their needs. The flexibility of the system makes it adaptable for various load profiles, ensuring maximum efficiency.

d. Easy Assembly and Handling: The BettaHaul Bearer System is designed for ease of assembly and handling. The clamping attachments, such as QuickClamp and FixedClamp, provide options for quick adjustment or a fixed setup, respectively. This simplicity reduces assembly time, streamlines loading processes, and improves overall efficiency.

Applications and Benefits:

a. Enhanced Load Safety: The BettaHaul Bearer System significantly improves load safety by minimizing load movement and the risk of damage during transportation. Its stable and secure platform ensures that loads remain intact, even during challenging road conditions.

b. Cost and Time Savings: Compared to traditional load securing methods, the BettaHaul Bearer System offers cost and time savings. The reduced need for excessive lashing and the system’s easy assembly contribute to faster loading and unloading processes, ultimately increasing productivity and reducing labor costs.

c. Durability and Longevity: The rubber bearers used in the BettaHaul Bearer System are highly durable and resistant to wear and tear. Unlike timber, they do not warp, crack, or require regular replacement, resulting in long-term cost savings and increased lifespan.

d. Versatile Applications: The BettaHaul Bearer System can be applied to various transportation scenarios, including steel transport, long-span loads, and curtain-sider or prairie-wagon rigids/trailers. The system’s adaptability allows it to cater to the specific needs of different industries and load profiles.

Customer Case Studies:

Several customers have experienced the benefits of the BettaHaul Bearer System:

Vulcan Steel: Vulcan Steel, with over 90 vehicles in operation, has utilized the BettaHaul system in its fleet for many years. The system’s consistency and durability have ensured the safe delivery of loads, resulting in undamaged goods.